Optimizing the structural design of perfume boxes to improve production efficiency and reduce costs can be done from multiple aspects, such as material selection, design simplification, production process optimization and supply chain management.

By reducing the thickness of cardboard or plastic, the material consumption can be reduced while ensuring the strength of the box body.

Adopting honeycomb structure or hollow design to improve stability and reduce material costs.

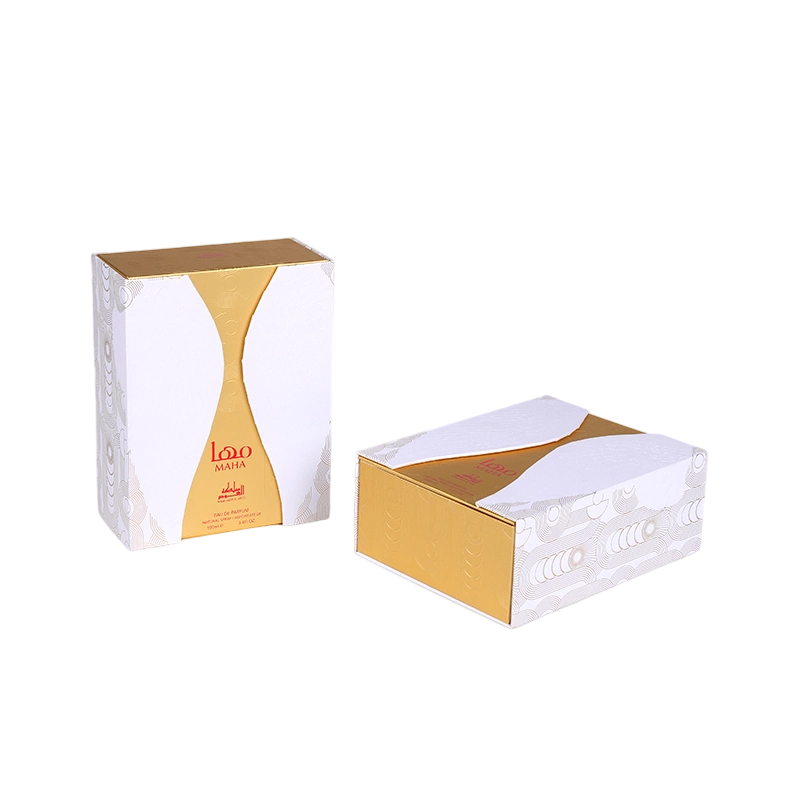

Designing compact packaging according to the shape and size of perfume bottles to avoid excessive gaps and reduce material waste.

Reduce unnecessary lining and fillers, and fix the position of perfume bottles by designing support structures.

Use lower-cost alternative materials, such as recycled paper or environmentally friendly plastics, to replace expensive high-end materials.

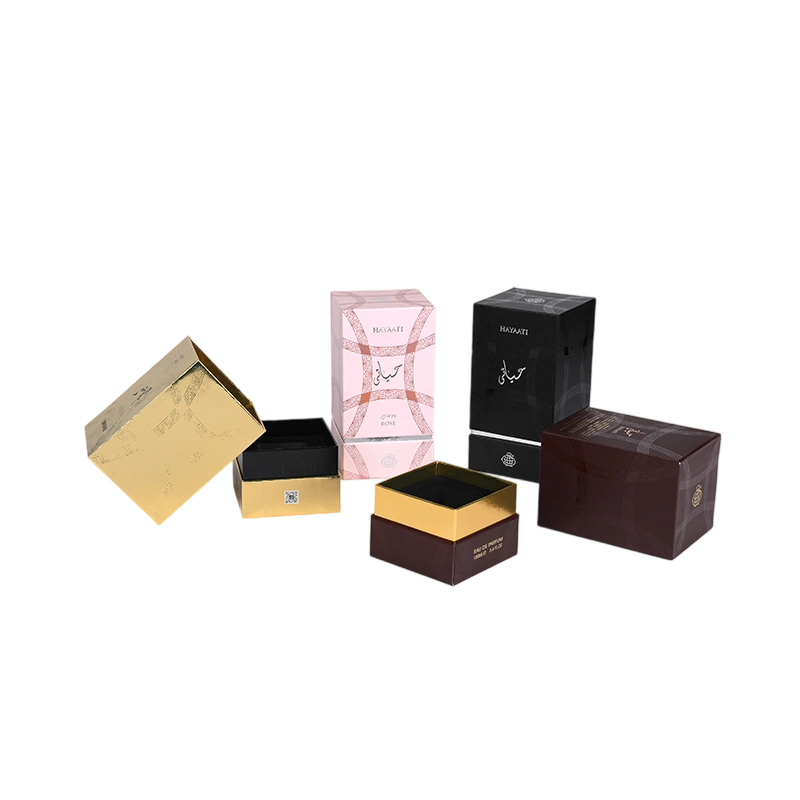

Optimize material combinations, such as using cardboard for outer packaging and foam materials for inner lining to balance aesthetics and economy.

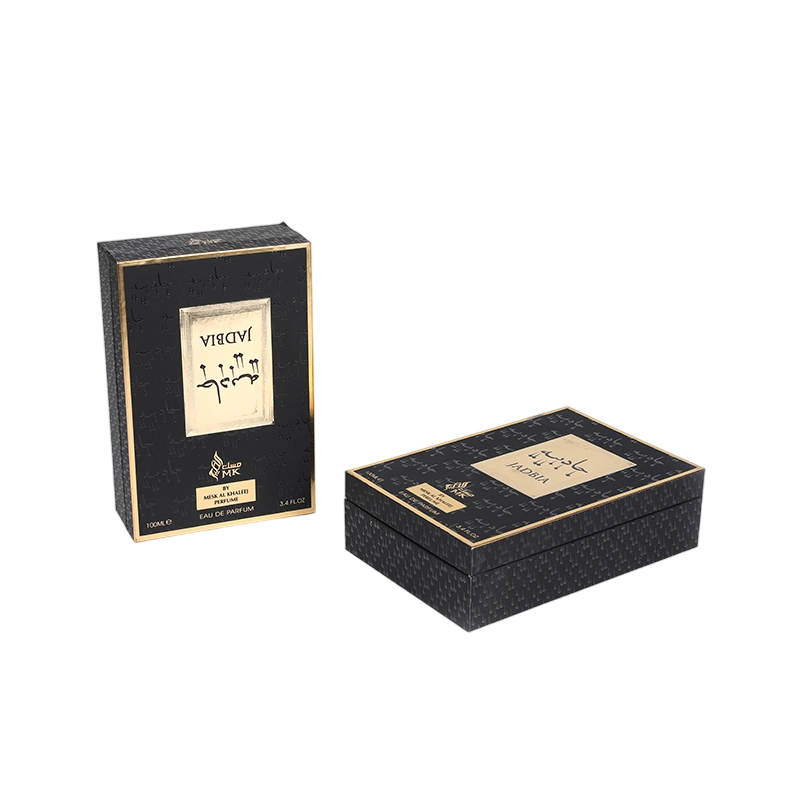

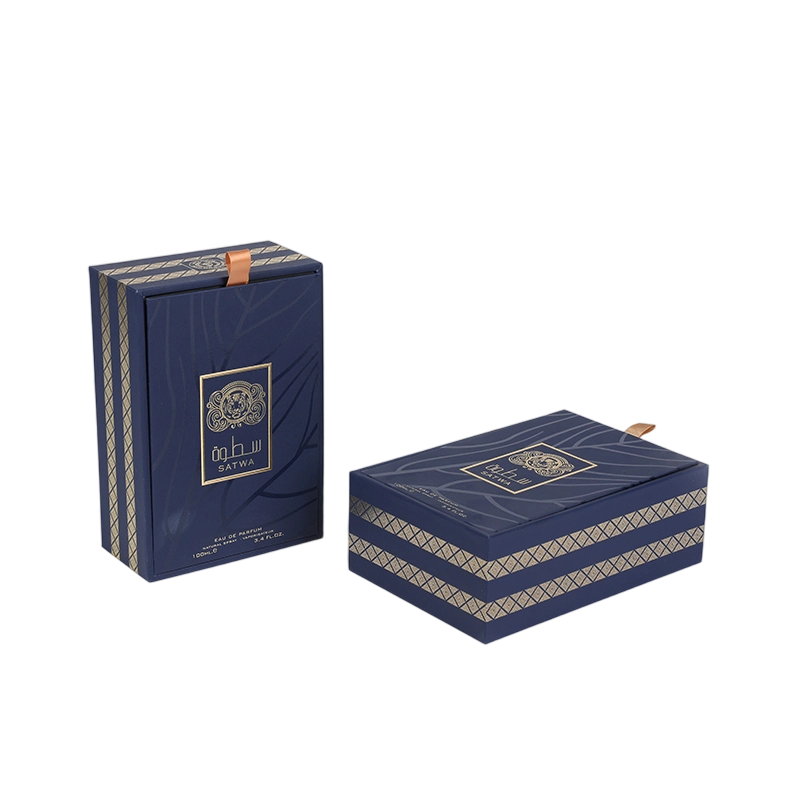

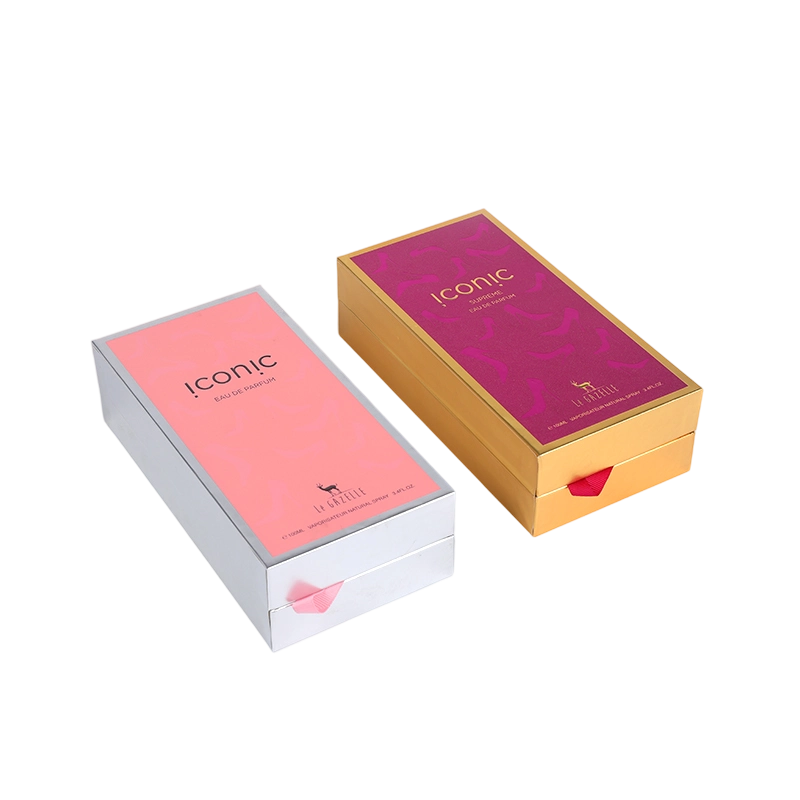

Optimize the box opening method, such as using simple plug-in or sliding structures to reduce folding and gluing steps.

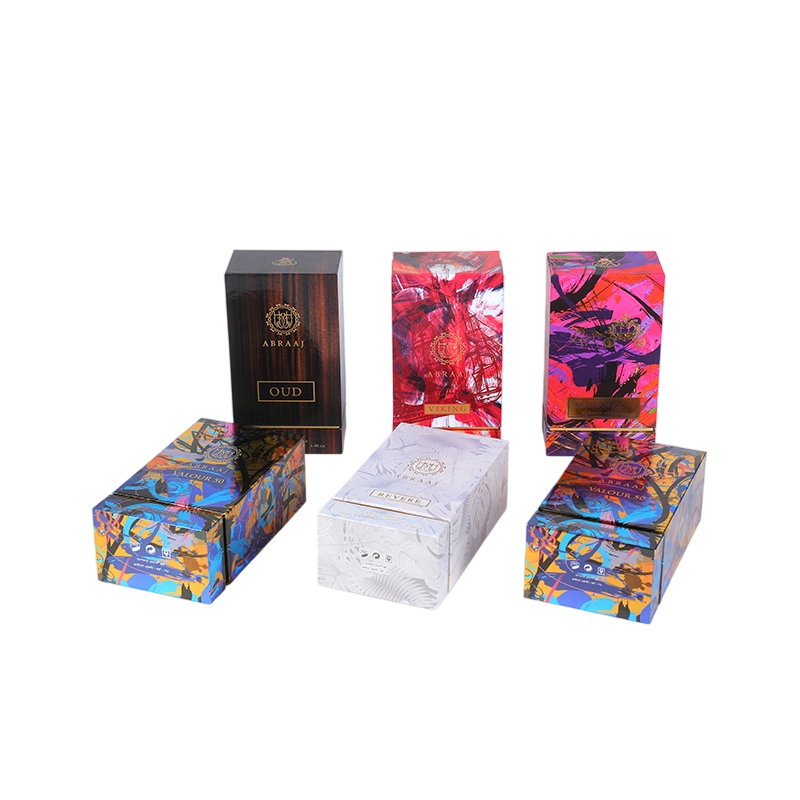

Reduce the complexity of decoration and avoid multi-layer structures or cumbersome hollow and engraving designs.

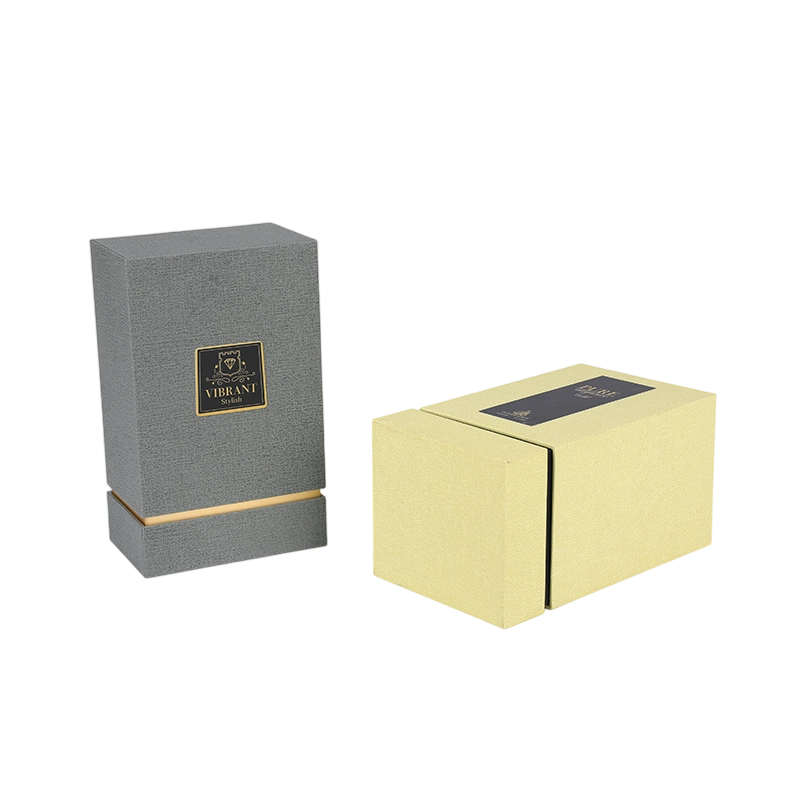

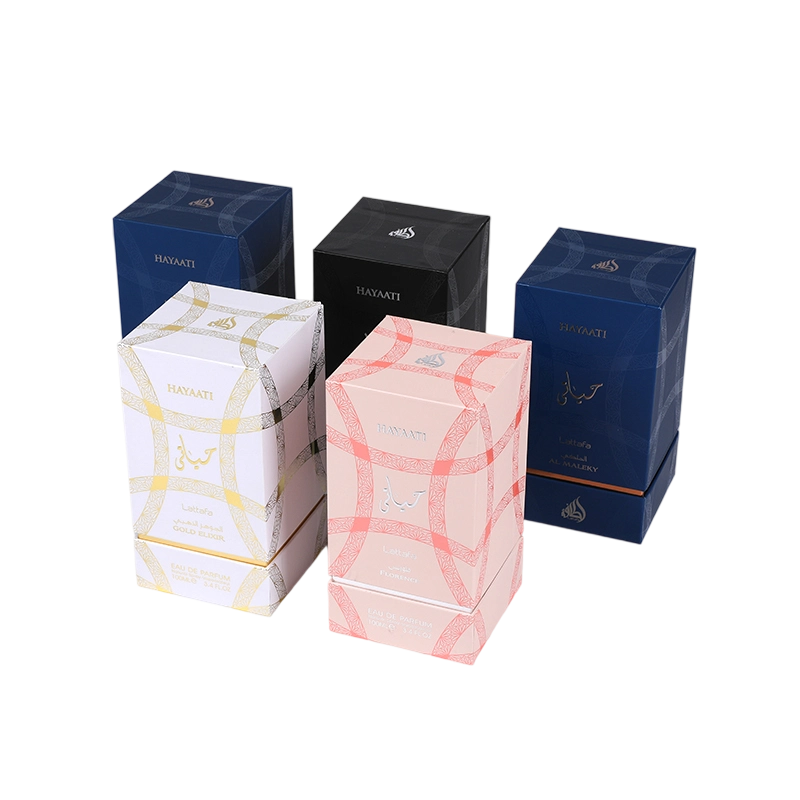

Use a unified box template to adjust the internal support structure according to the size of different perfume bottles to reduce mold production and design costs.

Use reusable design modules (such as standard-sized inner trays) to increase production line flexibility.

Design separate lids and bases into integrated structures to reduce the number of components and simplify assembly processes.

Optimize the position of accessories in the box (such as brochures, perfume trial cards) to avoid additional fixing or separation designs.

Introduce automated production lines, including cutting, folding, gluing and printing, to increase production speed and reduce labor costs.

Optimize the scheduling of packaging production and the design of assembly lines to reduce downtime and manual intervention.

Improve mold accuracy

Accurate mold design can reduce errors, reduce defective rates, and improve production efficiency.

Use multifunctional molds (such as adjustable molds) to adapt to the changing needs of different product sizes and save switching time.

Use digital printing technology or pre-printed films to reduce material waste and process costs during printing.

Use environmentally friendly inks or single-printing to cover full-color solutions to shorten printing time.

Establish long-term cooperative relationships with suppliers to obtain more stable prices and high-quality raw materials.

Give priority to local suppliers to reduce transportation costs and time.

The perfume box is designed with a foldable structure, which is convenient for large-scale storage and transportation, reducing logistics space requirements and transportation costs.

Use a stacked and stable outer packaging structure to improve transportation safety and reduce breakage rate.

Introduce 3D modeling and simulation technology to simulate mass production effects in the design stage to avoid problems that are difficult to produce in the design.

Use cloud platforms to share design drawings and modification opinions to accelerate design iterations.

Design as a multi-functional package (such as a gift box or storage box) to attract consumers to reuse and enhance brand value.

Add simple DIY assembly elements to allow consumers to participate in packaging design to enhance interactivity and experience.

Regularly collect feedback from production line employees and optimize structural details that affect efficiency in the design.

Adjust the design according to market feedback, remove structural functions that consumers do not pay attention to, and concentrate resources to enhance core value.

Use data to track cost and efficiency issues in the production process and accurately locate improvement points.

Perform KPI monitoring on the production process to ensure that the goal is achieved after optimizing the design.

By optimizing the structural design of the perfume box, production efficiency can be significantly improved and costs can be reduced while meeting aesthetics and functionality. This win-win strategy can not only bring direct economic benefits to the enterprise, but also enhance market competitiveness and consumer satisfaction.

English

English 中文简体

中文简体 عربى

عربى